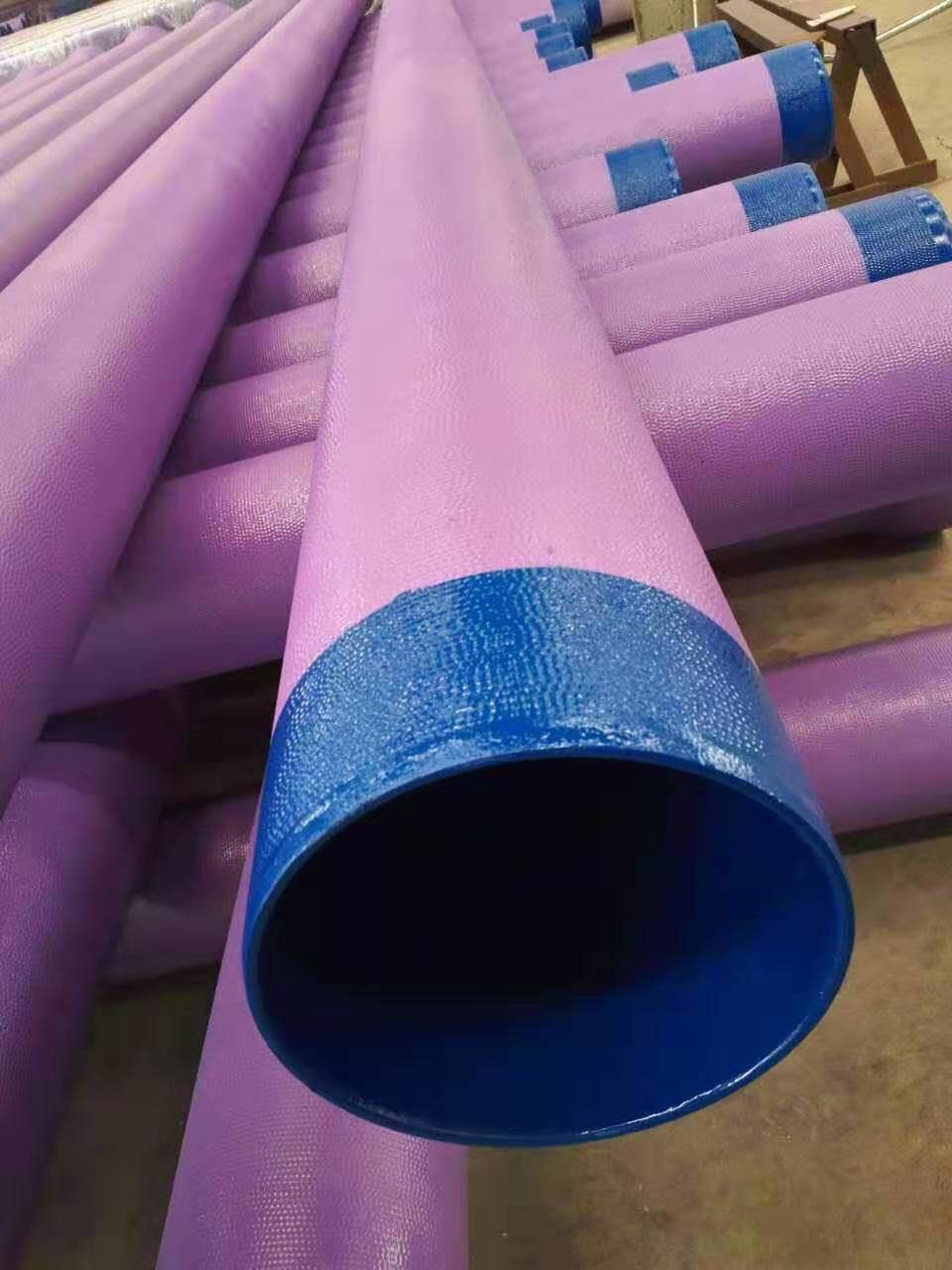

FBE Coated Ductile Iron Pipe

China top supplier ISO2531 EN545 Epoxy paint Ductile Iron Pipes C30,C40,C50,C100, K9,K12 drinking water

Standard:ISO2531/EN545

products strictly meet the below standards:

ISO 2531 Ductile iron pipes, fittings and accessories for pressure pipelines.

BSEN545 Ductile iron pipes, fittings and accessories and their joints for water pipelines. Requirements and test methods.

BSEN598 Ductile iron pipes, fittings, accessories and their joints for sewage application-requirements and test methods.

ISO7186 Ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings.

ISO4179 Ductile iron pipes for pressure and non pressure pipelines-Centrifugal cement mortar lining-general requirements.

ISO8179 Ductile iron pipes-External zinc coating.

ISO4633 Rubber Seals – joint rings for water supply, drainage and sewerage pipelines-specs for materials.

ISO 8180 Ductile iron pipes – Polyethylene Sleeve

| Item | Ductile iron pipe |

| Class | K9, K10, K11, K12,K9, K8, C25, C30, C40, etc. |

| Pipe Joint | push-on joint(Tyton joint), K type joint, self-restrained joint |

| Size | Outside Diameter: 98mm-1255mm Inside Diameter: 80mm-1200mm Wall Thickness: 6mm-153mm Length: 6m, cut to 5.7m, or as required. |

| Surface | External bitumen coating, or as required. |

| Application | Water supply project, drainage, sewage, irrigation, water pipeline, etc. |

| Package | Standard export package, or as required. |

| Price term | FOB, EXW,CIF, CFR, etc. |

| Payment | T/T, L/C, Western Union, etc. |

| Certificates | ISO, CE, BSI, WRAS |

Specifications:

1) The standard of pipe: ISO 2531, EN545 , EN598.

2) Pipe class: K9, C40, C30, C25, etc.

3) Pipe joint: push-on joint(Tyton joint), K type joint, self-restrained joint

4) Effective length: in general, the pipe length is 6m for bulk shipment and 5.7m for container shipment.

5) Internal lining: cement mortar lining as per ISO4179

6) Zinc coating: at least 130g/m2 as per ISO 8179

7) Bitumen painting: at least 70um as per ISO 8179

8) Gaskets are NBR rubber, natural rubber, SBR rubber or EPDM rubber ring as per ISO4633

9) DN 80 – 2,600 mm

10) High strength, lighter than gray iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life time

11) Checked by automatic inspection equipment

12) Chemical composition: (%)

3. a) C: 3.5 – 4.0

4. b) Si: 1.9 – 2.6

5. c) Mn:0.15 – 0.45

6. c) P: <0.06

7. d) S: <0.02

13) Mechanical properties

1. a) Tensile strength: ≥420MPa

2. b) Yield strength: ≥300Mpa

3. c) Hardness: ≤230HB

4. d) Elongation%: DN80 – 1000 ≥10 DN1200 – 2200 ≥7

14) Process and testing:

1. a) Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)

2. b) Casting (Visual check and weight check)

3. c) Heat treatment (Micro structure)

4. d) Hydrostatic test (Pressure test)

5. e) Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)

6. f) Zinc spraying (Thickness testing)

7. g) Lining and coating (100% visual check, thickness testing randomly)

8. i) Marking and packing (100% visual check)

15) The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc.

Packing: bundled with steel belts or in bulk

Shipment: in bulk or container

Description

Navigation

- Ductile Iron PIpe

- Ductile Iron Pipe Fitting

- 90°Double- Flanged Long Radius Bend

- All- Flanged Tee With 45°Angle Branch

- Bolted Gland Pipe Fittings

- Ductile Iron All Flanged Cross

- Ductile Iron All Flanged Tee

- Ductile Iron All Socket Tee

- Ductile Iron Double Flanged Bend-11.25°

- Ductile Iron Double Flanged Bend-22.5°

- Ductile Iron Double Flanged Bend-45°

- Ductile Iron Double Flanged Bend-90°

- Ductile Iron Double Flanged Duck foot Bend-90°

- Ductile Iron Double Socket / Socket Spigot Bend-11.25°

- Ductile Iron Double Socket / Socket Spigot Bend-22.5°

- Ductile Iron Double Socket / Socket Spigot Bend-45°

- Ductile Iron Double Socket / Socket Spigot Bend-90°

- Ductile Iron Double Socket Tee With Flanged Branch

- Ductile Iron Socket-Spigot Tee With Flanged Branch

- Flanged Bell mouth

- Flange Spigot

- Ductile Iron Flange Socket

- PIPE JOINT

- DISMANTLING JOINT

- REPAIR CLAMP

- VALVE

- FLANGE

- UPVC PIPE FITTING

- RUBBER SEALS

Contact us

Need more help?

We have a professional valves ,DI pipe and fittings team with more than 25 years experience , especially in universal range flange adapters,couplings,dismantling joints and also including PVC /PE pipe fittings .BS EN European standard and ANSI/ASME,DIN JIS.

8618724777835

jack@yongtongdipipe.com

linda@yongtongdipipe.com

sunny@yongtongdipipe.com

lucy@yongtongdipipe.com